How Box Gluing Machines Ensure Consistent Quality

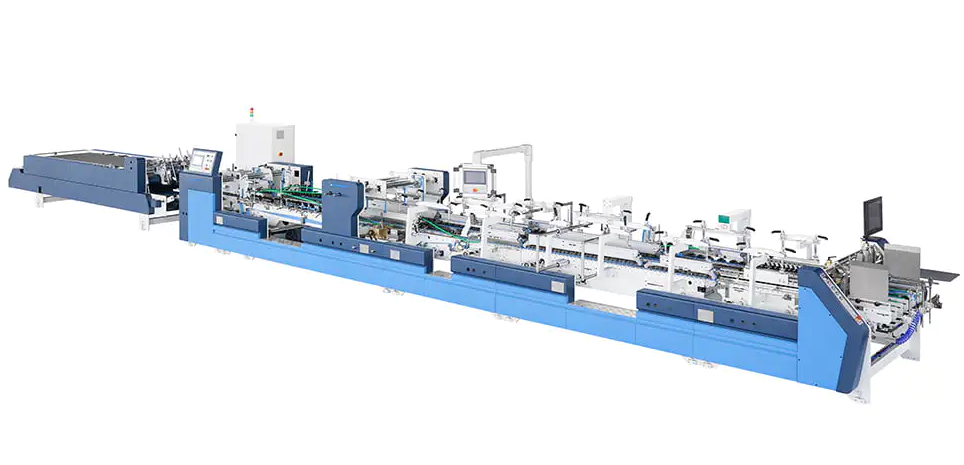

A box gluing machine is an essential tool in modern packaging operations. Its main purpose is to apply adhesive to paperboard blanks and form them into secure boxes. The machine provides a consistent and efficient method for producing packaging, which is especially useful for medium- and large-scale production.

Box gluing machines are designed to handle different types of cartons, such as folding cartons, tuck-end boxes, and set-up boxes. They usually include features like feeding systems, gluing stations, and alignment guides. The feeding system ensures continuous supply of blanks, while the gluing station applies the adhesive accurately to the designated areas. Alignment guides help maintain precise folding and positioning, reducing errors and minimizing waste.

The machine often allows operators to adjust speed, pressure, and glue application to match specific material types and thicknesses. Regular checks, including cleaning glue nozzles and inspecting rollers, are necessary to maintain optimal performance. Safety features are commonly included to protect operators during operation.

Box gluing machines are widely used in industries such as food packaging, electronics, and consumer goods. By automating the gluing process, manufacturers can reduce labor costs and maintain a higher level of quality control. Consistent production also helps meet delivery schedules and reduces the likelihood of packaging defects.

Overall, a box gluing machine plays a critical role in streamlining production processes. It improves efficiency, ensures uniform packaging, and supports various industries in meeting their packaging requirements reliably.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness