The Craftsmanship Behind Modern Brass Ball Valve Manufacturing

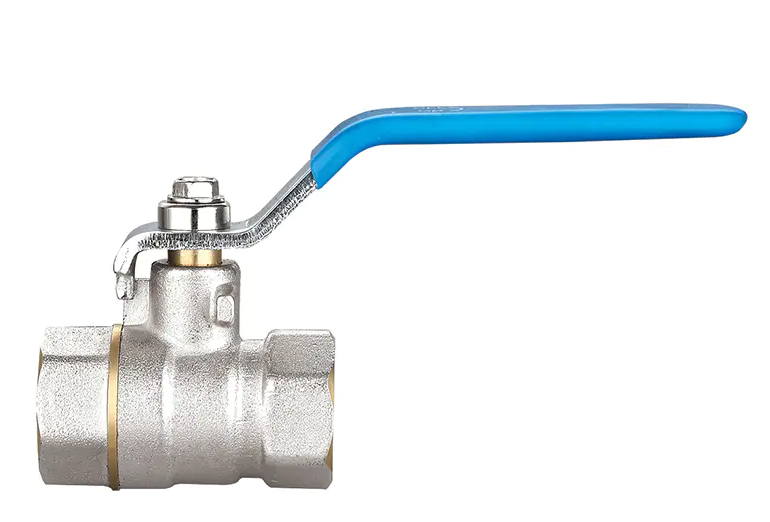

A Brass Ball Valve Factory focuses on producing durable and efficient valves that are essential for controlling fluid flow in plumbing, heating, and industrial systems. The precision and stability of these valves come from advanced machining, reliable materials, and rigorous quality inspection. Brass has become a preferred material due to its strength, corrosion resistance, and ability to maintain a tight seal under various pressure and temperature conditions.

In a typical Brass Ball Valve Factory, production starts with high-grade brass rods or bars that are cut and shaped through CNC machining. This process ensures accurate dimensions and smooth internal surfaces, which are crucial for leak-free operation. After machining, the valve components such as the body, ball, and stem are assembled with sealing elements like PTFE seats and O-rings to provide consistent sealing performance.

The ball valve’s structure is simple yet efficient. When the handle turns the internal ball, the bore aligns with the pipeline to allow flow or rotates 90 degrees to stop it completely. This design offers quick shut-off and control, making brass ball valves suitable for residential water systems, HVAC equipment, and industrial machinery.

Modern factories adopt automated assembly lines and testing equipment to improve precision and productivity. Each valve undergoes pressure and leakage tests to ensure it meets safety standards before packaging. Factories also pay close attention to surface treatment, applying polishing or nickel plating for enhanced durability and corrosion resistance.

In addition to standard models, a Brass Ball Valve Factory often manufactures customized products to meet specific needs. This includes variations in size, thread type, and handle design. Some valves are equipped with butterfly handles for compact spaces, while others feature extended stems for insulated systems.

With continuous technological progress and strict process management, brass ball valves remain essential components for both domestic and industrial applications. They provide reliable flow control, ease of use, and long service life, reflecting the precision and craftsmanship achieved in every factory that specializes in this field.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness