Choosing the Right Air Shaft for Industrial Applications

Introduction to Air Shafts

Air shafts are essential components in various industrial and manufacturing processes, particularly in roll-to-roll operations such as paper, film, and textile handling. These shafts allow rolls to be securely mounted, inflated, and released with ease. Working with a reliable Air Shaft Factory ensures that the shafts meet precise standards for performance, durability, and safety, which are critical in high-speed production environments.

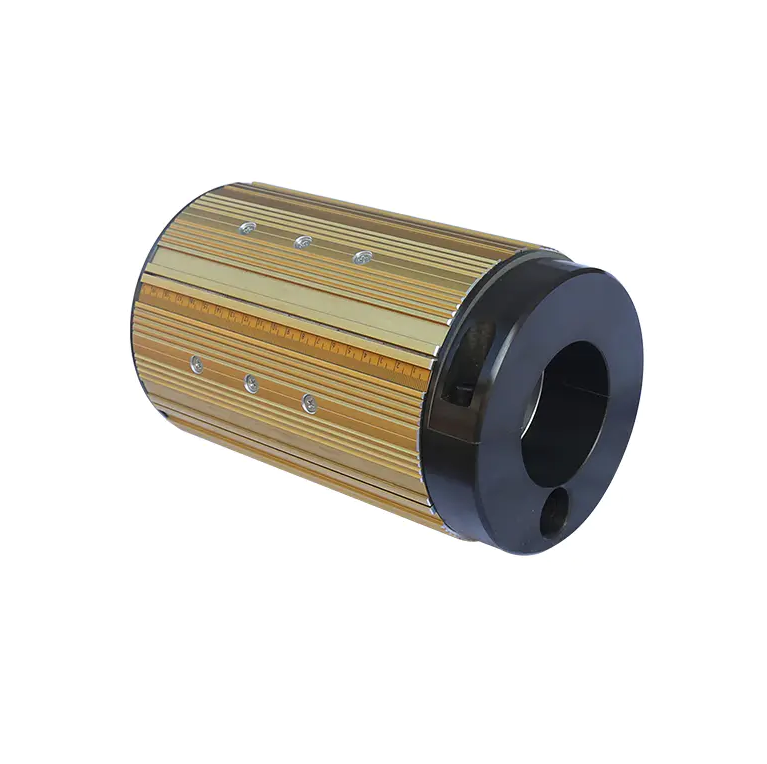

Structure and Material

Air shafts typically consist of a cylindrical metal tube with expandable bladders inside. When inflated, the bladders press against the roll’s core to provide a secure grip. High-quality shafts are made from durable steel, aluminum, or composite materials, providing both strength and corrosion resistance. The precision engineering from a reputable Air Shaft Factory guarantees minimal vibration, smooth operation, and long-lasting performance.

Functionality and Advantages

The primary function of an air shaft is to facilitate efficient loading, alignment, and unwinding of rolls. Inflatable bladders allow for quick installation and removal without damaging the material. This reduces downtime, increases productivity, and ensures consistent tension control. Air shafts also minimize the risk of material slippage or misalignment, maintaining product quality throughout the production process.

Safety and Reliability

Air shafts enhance operational safety by providing a stable and controlled method to handle heavy rolls. The controlled inflation mechanism prevents accidental release or roll damage. Using high-quality components from a trusted Air Shaft Factory ensures reliability even under continuous or heavy-duty use. This reliability helps avoid costly production interruptions and maintains workplace safety standards.

Industrial Applications

Air shafts are widely used in industries such as printing, paper converting, packaging, textiles, and plastics. They support a wide range of materials, including films, foils, and fabrics. Their ability to handle different core sizes and roll widths makes them versatile tools for modern manufacturing processes. By providing precise roll handling, air shafts contribute to higher efficiency and better product consistency.

Maintenance and Longevity

Maintenance of air shafts is straightforward but essential for longevity. Regular inspection of bladders, shafts, and bearings ensures smooth operation. Proper cleaning and lubrication prevent wear and extend the lifespan of the equipment. Selecting high-quality air shafts from a reputable Air Shaft Factory reduces maintenance needs and ensures consistent performance over years of industrial use.

Conclusion

Air shafts are indispensable in roll-handling operations, offering efficiency, safety, and precision. Their durable construction, easy operation, and versatile applications make them essential for modern manufacturing. Choosing a high-quality air shaft from a trusted Air Shaft Factory guarantees reliable performance, minimal downtime, and improved productivity across multiple industries.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness