Design and Applications of Plastic Sorting Box Mold

Introduction to Plastic Sorting Box Mold

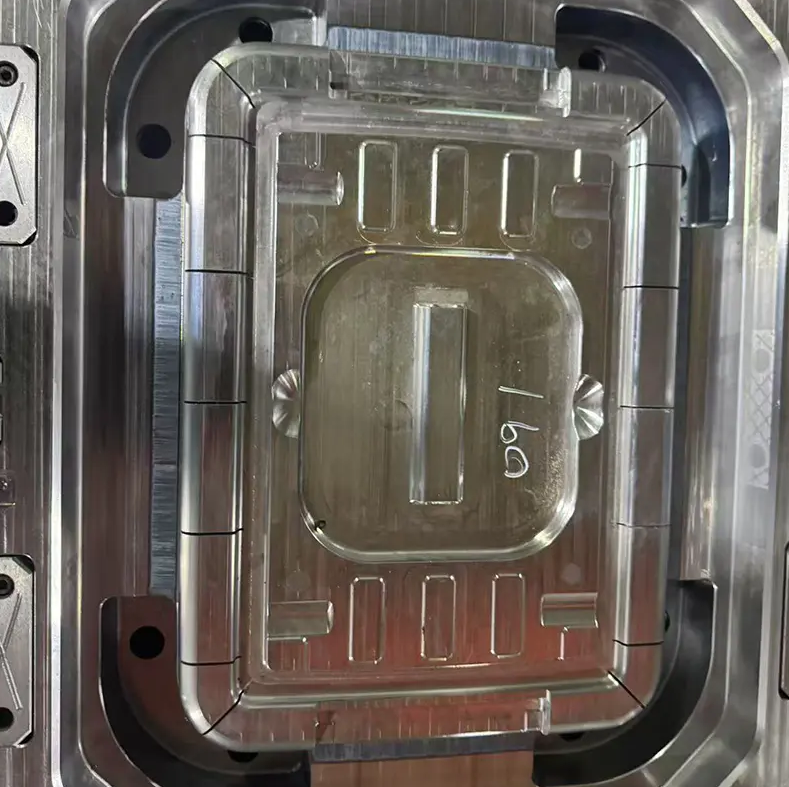

In modern manufacturing and logistics industries, the Plastic Sorting Box Mold plays a crucial role in producing standardized containers used for storage, transportation, and classification of goods. These molds determine not only the shape and size of sorting boxes but also their durability, functionality, and production efficiency. As demand for organized warehousing and automated logistics systems increases, the importance of high-quality molds becomes even more evident. Understanding how these molds are designed and applied helps manufacturers improve product consistency and market competitiveness.

Structural Design and Material Selection

The structural design of a sorting box mold directly affects the performance of the final plastic box. Mold designers must carefully consider wall thickness, rib placement, and edge reinforcement to ensure the box can withstand repeated loading and unloading. Material selection for the mold itself is equally important, as high-grade mold steel improves wear resistance and maintains dimensional accuracy during long production runs. A well-engineered Plastic Sorting Box Mold can achieve stable production while minimizing deformation, shrinkage, and surface defects in the finished product.

Manufacturing Precision and Production Efficiency

Precision machining is essential in mold manufacturing, as even small dimensional errors can lead to problems during mass production. Advanced CNC machining and polishing techniques allow molds to produce sorting boxes with smooth surfaces and consistent tolerances. High-precision molds also support faster injection cycles, which directly improves production efficiency. By reducing scrap rates and downtime, manufacturers can lower overall costs while maintaining reliable output quality.

Application in Logistics and Industrial Storage

Sorting boxes produced from these molds are widely used in warehouses, distribution centers, factories, and retail environments. Their uniform design enables easy stacking, automated handling, and efficient space utilization. In automated logistics systems, consistent box dimensions are essential for conveyor belts and robotic arms to operate smoothly. Therefore, the quality of the mold directly impacts the reliability of downstream logistics operations and overall supply chain efficiency.

Customization and Market Adaptability

Different industries often require sorting boxes with specific features such as ventilation holes, reinforced bottoms, or customized labels. Mold manufacturers can adapt designs to meet these needs by modifying cavity structures or adding interchangeable inserts. This flexibility allows companies to respond quickly to changing market demands without completely redesigning the mold. Customizable solutions enhance the value of plastic sorting boxes and expand their application range across various sectors.

Quality Control and Long-Term Value

Consistent quality control during mold production ensures stable performance over the mold’s service life. Proper heat treatment, surface finishing, and regular maintenance help extend mold longevity and reduce unexpected failures. A reliable mold not only guarantees product quality but also provides long-term economic benefits by supporting high-volume production with minimal defects. Investing in a well-designed mold is, therefore, a strategic decision for manufacturers aiming for sustainable growth.

Plastic sorting box molds are fundamental to efficient storage and logistics systems. Through careful design, precise manufacturing, and adaptable customization, these molds enable the mass production of durable and standardized sorting boxes. As industries continue to prioritize efficiency and automation, the role of advanced mold technology will remain essential in supporting modern production and distribution needs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness