Structural Stability of Industrial Plastic Trays

Importance of Stability in Industrial Tray Applications

Stability is a core requirement for industrial trays used in logistics, warehousing, and manufacturing environments. When goods are transported or stacked, even minor instability can result in load shifting, product damage, or operational inefficiency. For a Flat/grid Big Nine Feet Tray, stability depends on a combination of structural design, base support distribution, and surface configuration. Understanding how these elements work together helps users determine whether the tray is suitable for demanding transport and stacking scenarios.

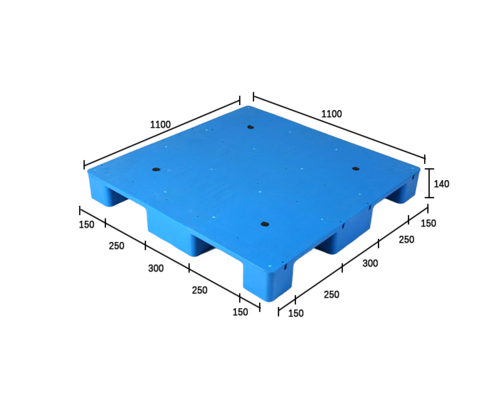

Base Structure and Nine-Feet Support Distribution

One of the most important contributors to tray stability is the nine-foot base structure. This design distributes weight evenly across multiple contact points, reducing localized stress and minimizing rocking during movement. When a tray is placed on uneven floors or pallet racks, the nine support feet help maintain consistent ground contact. This balanced load transfer improves stability during both static stacking and dynamic transport, particularly when trays are moved by forklifts or automated handling systems.

Flat Versus Grid Surface Influence

The surface design of a tray significantly affects how loads behave during transport. A flat surface provides uniform contact for boxed or rigid items, reducing the likelihood of tilting. In contrast, a grid surface enhances friction and airflow while offering additional resistance against lateral sliding. For the Flat/grid Big Nine Feet Tray, combining surface rigidity with structural reinforcement helps prevent cargo from shifting during acceleration, braking, or vibration commonly experienced during transport.

Structural Rigidity and Deformation Control

Stability during stacking is closely linked to how well a tray resists deformation under load. A rigid structure ensures that the tray maintains its shape even when multiple units are stacked vertically. If a tray bends or twists under weight, the stacked load above may become misaligned, increasing the risk of collapse. Reinforced ribs and optimized wall thickness allow the tray to remain dimensionally stable, supporting consistent stacking alignment and long-term reliability.

Stacking Alignment and Interlocking Behavior

Effective stacking stability also depends on how trays align with one another. Properly designed trays feature consistent edge geometry and base alignment, ensuring that upper trays sit securely on those below. The nine-foot layout helps guide vertical load paths directly downward, minimizing horizontal displacement. This alignment is especially important in high-bay storage systems where stacked trays must remain stable over extended periods without manual adjustment.

Performance During Transportation

During transportation, trays are subjected to vibrations, sudden stops, and directional changes. Stability under these conditions requires both a low center of gravity and secure load positioning. The wide footprint created by the nine-foot base reduces tipping risk, while the tray’s structural design limits lateral movement. As a result, the tray performs reliably on conveyor belts, trucks, and automated guided vehicles without excessive shifting or oscillation.

Influence of Load Type and Weight Distribution

Stability is not only determined by tray design but also by how loads are arranged. Even a well-designed Flat/grid Big Nine Feet Tray performs best when weight is evenly distributed across its surface. Concentrated loads placed at edges or corners may compromise stability, especially during stacking. However, the reinforced base and grid structure help mitigate these risks by spreading forces across multiple support points, maintaining balance even under uneven loading conditions.

Long-Term Stability in Repeated Use

In industrial environments, trays are often reused over long periods. Repeated loading and unloading cycles can gradually affect stability if the structure is not adequately reinforced. High-quality trays maintain consistent performance by resisting material fatigue and preserving structural integrity. This ensures that stacking and transport stability remain reliable throughout the tray’s service life, reducing replacement frequency and operational downtime.

Stability during transport and stacking is a defining performance factor for any industrial tray system. Through a combination of nine-foot base support, optimized surface design, and structural rigidity, a Flat/grid Big Nine Feet Tray can deliver dependable stability in demanding logistics environments. When properly loaded and used within its design limits, it provides secure stacking, controlled movement, and long-term reliability, making it a practical solution for modern material handling operations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness