How Kettle Couplers Prevent Electrical Hazards

Understanding Dry Boil Protection in Kettle Couplers

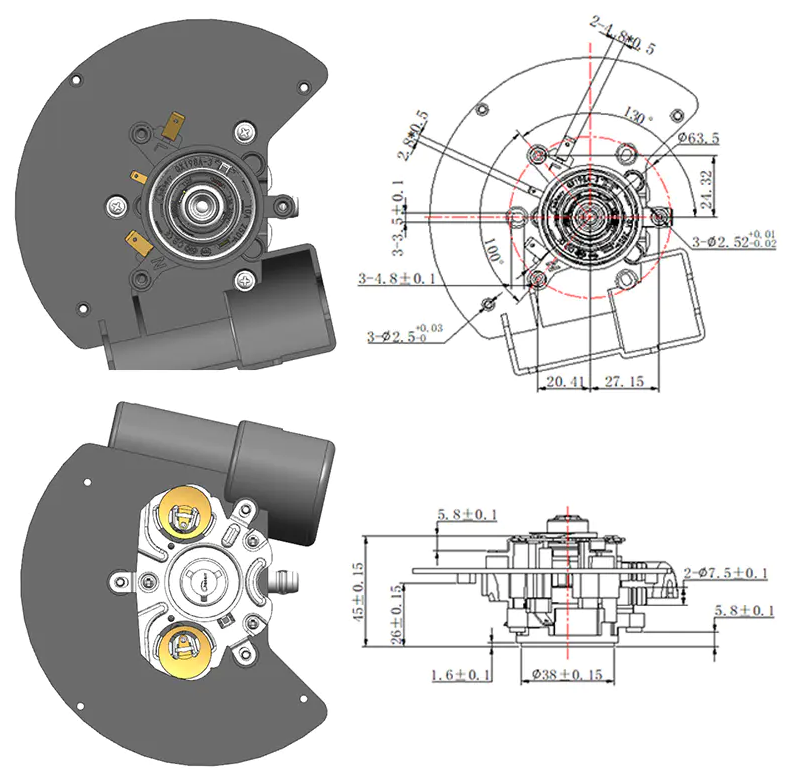

A Dry Boil Protection Kettle Part Coupler is a crucial component designed to enhance the safety of electric kettles. Its primary function is to prevent the kettle from continuing to heat when there is insufficient water inside, which can cause overheating and potentially damage the appliance. Beyond temperature regulation, modern couplers incorporate electrical safety measures that minimize the risk of leakage currents. By ensuring that the electrical connections are well-insulated and that the circuit interrupts power when abnormal conditions are detected, the coupler plays a central role in protecting users from electric shocks and other hazards associated with dry boiling.

How Coupler Design Prevents Electrical Leakage

The design of a dry boil protection coupler focuses on creating secure insulation barriers between live electrical contacts and any part that may come into contact with water or the kettle body. Typically, high-quality plastic or thermoset materials are used to house the metal connectors, ensuring no direct path for electricity to escape. Additionally, spacing between components is carefully calculated to comply with safety standards, reducing the likelihood of arcing or short circuits. Some couplers also include sealing elements that block moisture from entering sensitive areas, which is particularly important in preventing leakage currents when the kettle is exposed to steam or condensation during operation.

Integrated Safety Mechanisms

Beyond insulation, the coupler works in tandem with sensors and thermostats to provide multiple layers of protection. In the event of dry boiling, the thermostat triggers the coupler to disconnect power immediately, stopping the heating element from generating excessive heat. This automatic cut-off mechanism not only prevents damage to the kettle but also significantly reduces the risk of electric shock. Certain designs also incorporate redundant safety circuits that provide backup protection if the primary sensor fails, ensuring consistent safety performance under various operating conditions.

Benefits of Enhanced Electrical Safety

The anti-leakage features of a Dry Boil Protection Kettle Part Coupler provide tangible benefits to both household and commercial users. Users can safely operate kettles without worrying about accidental contact with live electrical components. In addition, these features increase the overall reliability of the appliance, minimizing maintenance needs and extending its lifespan. For families, the design reduces the risk of injury to children or pets who might accidentally come into contact with the kettle during operation. For industrial applications, these safety measures help maintain compliance with electrical standards and protect against costly accidents.

A Dry Boil Protection Kettle Part Coupler is more than just a connector; it is an integral safety device that combines dry boil prevention with electrical leakage protection. Through careful material selection, precise insulation, and integration with temperature sensors, the coupler ensures that the kettle operates safely under normal and abnormal conditions. Investing in kettles with high-quality couplers not only safeguards users but also enhances the durability and reliability of the appliance, making it an essential feature in modern electric kettle design.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness