Understanding BTB Connector Compatibility Across Applications

Introduction to BTB Connectors

A BTB Connector (Board-to-Board Connector) plays a critical role in modern electronics by providing a reliable interface between two printed circuit boards (PCBs). One of the most common questions from designers and engineers is how compatible these connectors are with different types of PCBs, layouts, and electronic components. Compatibility is influenced by factors such as connector pitch, number of pins, mechanical design, and electrical specifications. Ensuring proper compatibility is essential for achieving reliable signal transmission, mechanical stability, and long-term performance in electronic systems.

Factors Affecting Connector Compatibility

Compatibility of a BTB connector depends on multiple design and functional factors. First, the pitch and number of pins must match the corresponding pads on the PCB to ensure proper electrical connections. Mismatched pitch or missing pins can lead to incomplete circuits or signal failures. The physical dimensions of the connector, including its height and width, also play a role in ensuring that it fits within the design constraints of the assembly. The connector housing must align accurately with the board to prevent mechanical stress during insertion or operation.

Electrical and Signal Considerations

In addition to mechanical factors, electrical compatibility is crucial. The connector must support the voltage, current, and signal frequencies required by the application. High-speed or high-frequency signals require connectors with controlled impedance and minimal crosstalk to maintain signal integrity. Using a BTB connector with insufficient electrical specifications can result in signal degradation, overheating, or even failure of sensitive components. Choosing a connector designed to meet or exceed the electrical requirements ensures reliable operation and compatibility with the electronic system.

Environmental and Operational Factors

BTB connector compatibility is also affected by environmental conditions. Temperature, humidity, vibration, and exposure to dust or corrosive substances can all influence performance. A connector may be electrically compatible with a board but fail mechanically or thermally if it is not designed to withstand these conditions. Manufacturers often provide BTB connectors rated for industrial, automotive, or consumer-grade environments. Selecting a connector with appropriate environmental ratings ensures that it will maintain performance under the expected operating conditions.

Connector Standards and Interchangeability

Standardization is another important aspect of compatibility. Many BTB connectors follow industry standards regarding pitch, layout, and electrical characteristics. Using standardized connectors improves interchangeability, reduces design errors, and simplifies sourcing of replacement parts. However, proprietary designs or custom connectors may offer specific advantages, such as compact size or enhanced durability, but require careful matching with the corresponding board. Engineers must balance the benefits of standardized connectors with the specific needs of their project.

The compatibility of a BTB Connector depends on mechanical design, electrical specifications, environmental tolerance, and adherence to standards. Ensuring proper pin alignment, pitch, and board spacing is essential for physical integration, while selecting connectors with adequate voltage and current ratings guarantees electrical reliability. Environmental considerations and adherence to standardized designs further improve long-term performance. By carefully evaluating these factors during the design phase, engineers can select BTB connectors that offer seamless compatibility and reliable operation in a wide range of electronic applications.

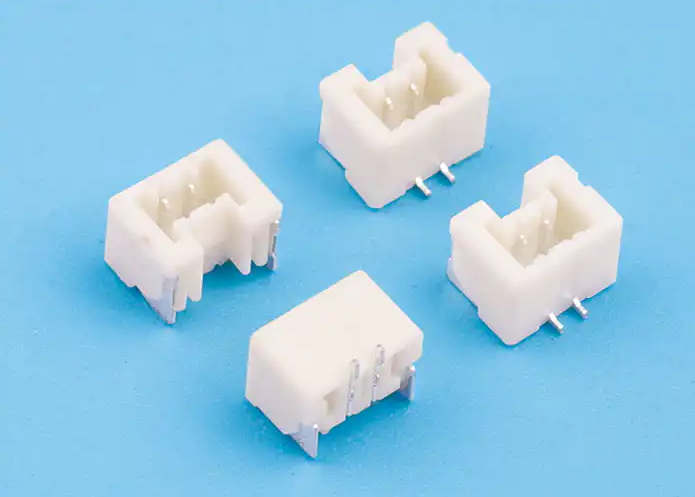

1、CKT: 2Pin

2、Current rating: 1A AC/DC

3、Voltage rating(max): 125V, AC/DC

4、Working Temperature: -25°C~+85°C,

(Including temperature rise in applying electrical current)

5、Contact resistance:value s20mΩ

After environmental testing≤30msΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 500VAC(rms)

8、Applicable PCB board thickness: 1.6mm to 2.0mm

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness