Optimizing Molds for Automotive Plastic Parts

The Importance of Plastic Automobile Parts Mold

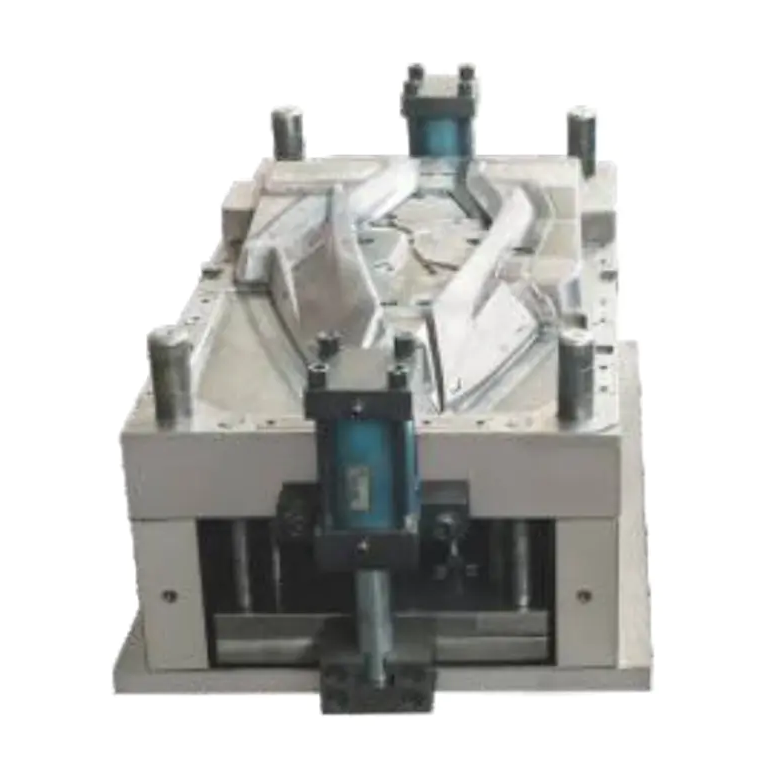

Plastic Automobile Parts Mold plays a crucial role in modern vehicle manufacturing, supporting the production of interior trims, bumpers, dashboards, and functional components under the hood. As automotive manufacturers demand lighter vehicles to improve fuel efficiency and reduce emissions, precision molding becomes essential. A well-designed mold ensures dimensional stability, high surface quality, and consistent structural strength, all of which are critical in automotive applications.

Because automotive components often require complex geometries and strict tolerance standards, the Plastic Automobile Parts Mold must be engineered with advanced design tools and precise machining technologies. Early-stage simulation analysis helps predict material flow, shrinkage, and potential defects, allowing engineers to refine the structure before production begins. This proactive approach reduces trial costs and shortens development cycles.

Structural Design for High Performance

Automotive parts frequently feature thin walls, reinforcement ribs, and intricate clips or fastening systems. Mold design must account for these features while maintaining balanced material flow and adequate venting. Proper gate placement reduces weld lines and stress concentration, improving both appearance and mechanical performance.

Cooling system design is another decisive factor. Uniform cooling ensures even shrinkage and prevents warping, especially in large parts such as door panels or instrument panels. Efficient cooling channels also shorten cycle time, increasing production capacity without sacrificing quality. Structural reinforcement within the mold base further enhances rigidity, preventing deformation during high-pressure injection.

Material Selection and Durability

Selecting the appropriate mold steel is vital for long-term reliability. Automotive production typically involves high-volume runs, requiring hardened tool steels with excellent wear resistance. Surface treatments such as nitriding or coating improve corrosion resistance and extend service life, particularly when processing reinforced plastics like glass fiber–filled materials.

In addition to steel quality, component precision contributes to overall durability. High-accuracy CNC machining and EDM finishing ensure tight tolerances, which are essential for parts that must fit seamlessly during vehicle assembly. By combining robust materials with precise manufacturing processes, mold longevity can be significantly improved.

Quality Control and Process Stability

Consistency is fundamental in automotive manufacturing. Even minor dimensional deviations can lead to assembly issues or functional defects. Advanced inspection equipment, including coordinate measuring machines and optical scanning systems, helps verify mold accuracy before mass production.

Process stability also depends on well-designed venting and ejection systems. Proper venting eliminates trapped air, reducing burn marks and incomplete filling. A reliable ejection mechanism prevents surface damage and maintains cycle efficiency. Through comprehensive quality control measures, manufacturers ensure that each molded part meets strict automotive standards.

Adapting to Industry Trends

The automotive industry is evolving rapidly, with electric vehicles and smart technologies driving new design requirements. Lightweight materials, integrated electronic housings, and aesthetic surface finishes demand greater mold sophistication. Modular design concepts allow faster updates and easier maintenance, enabling manufacturers to respond quickly to model changes.

Sustainability considerations are also influencing production strategies. Optimizing material usage, improving energy efficiency, and supporting recyclable plastics contribute to environmentally responsible manufacturing. Continuous innovation in mold engineering ensures compatibility with these emerging trends.

Plastic Automobile Parts Mold remains a foundation of efficient automotive production. By integrating precise design, durable materials, advanced cooling systems, and strict quality control, manufacturers can deliver high-performance components that meet evolving industry standards. In an increasingly competitive market, investing in reliable mold technology ensures both productivity and long-term success.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness