Practices for Biomass Hot Boiler Heater Maintenance

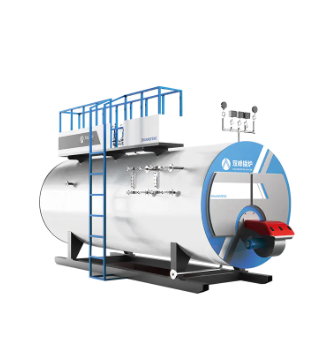

The biomass hot boiler heater is a versatile solution for providing heat in commercial and industrial settings. By burning organic fuels like wood chips or agricultural residues, it generates hot water or steam with high thermal efficiency.

Operators of biomass hot boiler heaters benefit from stable temperature control, supporting industrial processes and building heating. Proper maintenance, including fuel quality monitoring, ash removal, and cleaning of heat exchangers, ensures consistent performance. Automated control systems in some models enhance combustion efficiency and reduce operational variability.

Environmental considerations are important. Biomass boilers produce lower emissions than traditional fossil-fuel systems, helping facilities meet regulatory requirements while reducing carbon impact. Flexible fuel options and scalable system sizes allow the biomass hot boiler heater to serve small buildings or large district heating networks without compromising efficiency.

In summary, the biomass hot boiler heater offers reliable, efficient, and environmentally friendly heating. Following best maintenance practices ensures optimal performance, long service life, and consistent temperature output for various commercial and industrial applications.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness